Tali Digital Branding Solutions claims its highest priority is producing work that surpasses clients’ expectations. A discussion with founder and owner Orlando De Abreu shows that Tali embraces the technology to do this while back office systems and client requirement information are imperatives.

A slick operation

‘To be slick and to run a super slick operation’, is the way Orlando describes his ideal. He achieves this with automated processes; high-end machinery; a controlled environment; and the ability to conceptualise and tailor solutions for clients.

Long-term solutions

The company, which found a niche in offering large-scale out-of-home branding solutions such as billboards, truck tarpaulins building and boundary wraps, among others including smaller solutions such as point of sale,flags, banners, stickers and posters, is focused on long-term solutions. “We approach this from several angels,” says Orlando.

He says that they always try understand all of a client’s needs “before we even begin”. Some of the questions clients can typically expect when doing business with Tali are: where is it going; why is it going there specifically; what is the duration required; and what type of exposure are you looking for?

Correct solutions

“Often clients know what they want from a visual perspective,” he says, “but from a feasibility perspective (taking into account Tali’s standard questions) alternate and tailored solutions may work better than the client’s original idea.” This can be because of a number of variable factors, medium transportation among them. “The beauty of having a range of printing and printing-related equipment with so much adeptness and capability is the ability to provide correct long-term solutions.”

Arsenal of equipment

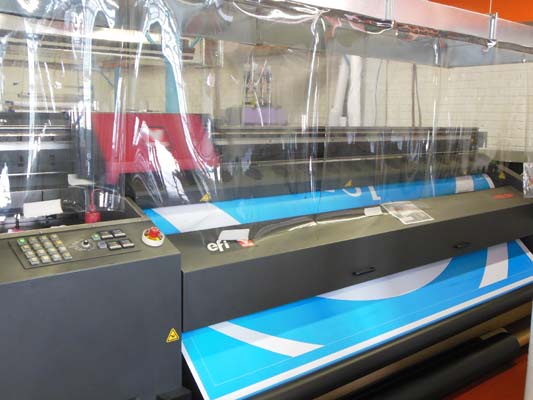

While Tali has expanded in its eight-odd years of existence and updated equipment and machinery accordingly, technological updates and physical expansion is ongoing. At the moment Orlando’s arsenal of up-to-date technological innovations include: Océ Arizona 550 GT – a UV curable flatbed printer with a white digital printing option – used for the corrugated and foam board, Chroma deck, correx, acrylics etc; two Roland Eco Solvent printers, which achieves photographic results at 1440 x 720 dpi, used for high resolution point of sale items; an HP Latex printer for posters,backlits, banners, self-adhesive vinyls, etc; a Mimaki JV 5 320 DS for all fabric printing; a Monti press otherwise known as a calendaring press or dye sublimation press; Vutek 3360 for billboards, truck tarpaulin and PVC banners; as well as a 1.6m wide laminator, among others.

Value-add

“My aim is client satisfaction and long-term relationships,” Orlando points out, “rather than just quisk sales turnover. Our point of difference is our value-add! We ensure our machines are applied to the substrate to ensure the best end-product (Orlando visits four international trade shows annually to source potential new substrates). I also ensure that the client’s experience is as hassle- or worry-free as possible – right through to erecting signage on site.”

Special equipment

The UV flatbed, which is relatively new, has allowed Tali to enter new markets and refine their offering. Irregularly shaped flat objects can act as substrate; and image detail is near photo quality as imaging technology produces ink droplets from 6 to 42 picolitres. It can also print on rigid and flexible media.

Complementing Tali’s service offering of finding and delivering the best possible medium for a marketers needs is the fact that the flatbed enables the branding company to offer bespoke limited quantity – as few as one or two – solutions at minimal cost.

‘Cutting’ edge & automation

Enhancing the entire operation is the acquisition of a ZUND cutter. “The ZUND cutter will streamline our business as it enables us to convert everything we print by robot,” Orlando points out, rather enthusiastically. “While our success in converting by hand is nothing to be sniffed at, robotising our operation limits human error. In addition, we’ll be able to convert about 12 times faster than we currently do, offering an faster turn-around time for clients.”

As Tali’s current turn-around time is less than the three to five working days usually quoted, a 12-times improvement on the converting process should put them leaps and bounds in front of potential competitors. “Going forward, my vision is to automate as much of our processes as possible enabling staff currently used in certain areas to learn and grow in others.

Back office

Running an ‘automated ship’ brings us to the behind the scenes operations where Orlando has a state-of-the-art MIS production system. This enables management to control work centres; know which machines are available for what projects and when; do forecasts to determine time requirements for varying print orders.. “This all goes to the swift and streamlined running of our operation with, as always, optimal client service our goal.”

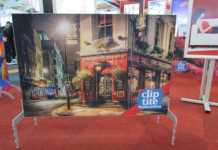

Tali-owned solution

Tali owns the brand Efex Portable Displays. The Efex Econo Pull Up Screen is unique to the company. “Pull ups or roll ups have been around for years,” Orlando says, “but the Econo Pull Up Screen is, without a doubt, the strongest econo roll out graphic in the South African market.” He credits this to the fact that the product comprises a single piece extrusion which makes the centre section extremely strong. “It cannot be bent by hand!” Orlando points out. “We have tweaked the product over time and it evolves constantly. We have just changed our fabric banner wall systems to thicker extrusions and our clipping system is unique making use of male and female pressure sensitive clips as opposed to metal clips.”

Harnessing expertise

While, inevitably, some requirements have to be outsourced Tali has made a concerted effort to keep as much as possible in-house to avoid any limitations derived by using third party suppliers.

To this end Tali has an in-house stitching department with multiple sewing machines; a high frequency welding operation; and UV varnishing, mounting and lamination are also done in-house.

There is no doubt that Orlando runs a very slick operation at Tali; and it seems he is on course to be a “super slick operation”. Watch this space!

*For additional information and to view a comprehensive brochure listing all solutions and machinery visit www.tali.co.za or call them on 011 786 3147.